The Intricacies and Significance of Diecasting in Fashionable Manufacturing

The Intricacies and Significance of Diecasting in Fashionable Manufacturing

Blog Article

Diecasting is one of the most important processes for modern manufacturing. It plays an essential role in producing sophisticated metal parts with precision and efficacy. The process involves pushing molten metal under high pressure into a mold cavity, producing parts with exceptional dimensional accuracy and high quality surface finishes. With the development of industries and the need for top-quality parts grows, diecasting is continuing to prove its value specifically in the areas that require the mass production of complicated parts. This article explores the process of diecasting, its advantages, material choices, and its extensive applications across various sectors.

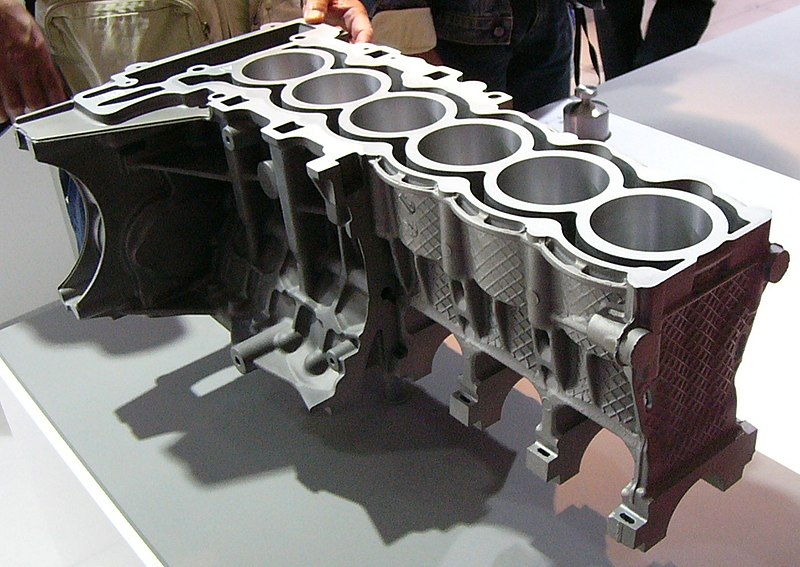

In the center of diecasting is the mold, also known as a"die" that is carefully designed and constructed from solid steel, which is hardened to resist the extreme conditions of this casting. Die design is important, as it is required to support the molten metal's flow as well as solidification, while maintaining tight tolerances to ensure high-quality. In the process of diecasting it is the case that metals like aluminum, zinc, magnesium and copper are heated up until they get molten. This molten steel is put into the die cavity with high pressure, and fills every crevice and crevice of the mold. Rapid cooling and the hardening of the material result in pieces that display high dimensional precision and polished surface, typically not requiring additional manufacturing or finishing.

One of the major benefits that diecasting has is its efficacy when it comes to mass production. After the dies have been made and the process begins, it is repeated thousands or hundreds of times, with no variation in pieces. This high repeatability is crucial for businesses that require huge amounts of the same components. In addition, diecasting is renowned for its efficiency in manufacturing. This process produces less waste compared to different metal-forming methods in that excess metal could be recycled and reused. This not only reduces cost of materials but it also contributes to better sustainable production practices. This combination of accuracy, speed and material efficiency makes diecasting an appealing alternative for large-scale production.

Diecasting also excels in producing products with exceptional mechanical properties. The rapid cooling of the liquid metal that is formed during the process of casting results in an extremely fine-grain design, which increases the toughness and endurance of the finished product. Dies makes diecast parts ideal for use in applications that demand superior performance and durability. For example, in the automotive industry, diecast parts are used in the transmissions, engines and structural elements, where their strength-to-weight ratio is critical for the safety of the vehicle and its efficiency. In aerospace diecast components aid in the development of lightweight yet robust structures, essential for optimizing performance and efficiency in fuel consumption. To receive added details kindly go to Senadiecasting

The choice of materials in diecasting significantly influences the properties and efficiency of the final product. Aluminum is one of the top choices because of its superior strength-to-weight ratio, resistance to corrosion, and thermal and electrical conductivity. These properties make aluminum ideal for aerospace and automotive uses in which weight reduction is essential. Zinc alloys provide high strength and ductility. This makes them ideal for components that require fine detail and long-lasting. Magnesium alloys weigh the least metallic structural elements, offering the advantage when weight savings are paramount. Copper alloys are more rarely used, are valued for their high electrical conductivity and the resistance to corrosion. Each alloy has distinct advantages making it possible for manufacturers to pick the most suitable option to meet the application they are looking for.

Diecasting is a sophisticated manufacturing process that combines accuracy, precision and versatility. The ability of diecasting to create sophisticated, high-end components that have excellent mechanical properties makes it essential in all sectors. Diecasting's effectiveness when it comes to mass production, with its material and price benefits, prove its importance for modern manufacturing. In the future, as industries demand robust and high-performance components, diecasting will remain an essential technology that drives forward the development of advanced products that meet all the demands of a constantly changing market. Due to its continuous evolution and application diecasting illustrates the interplay of manufacturing excellence and engineering prowess.